Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763

DIN 22252 chains, are tested and calibrated chains that you can use safely manufactured for conveyors used in mines. After the heat treatment performed specially in our induction machines, especially the proof and breaking load elongations are safely provided.

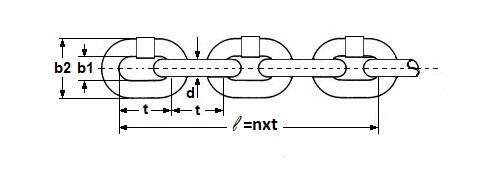

Marking of round-steel chain grade 2, nominal size 26×92 mm, lenght allowance according to table 1:DIN 22252-2-26×92-1

DIMENSIONS AND WEIGHTS

l |

||||||||||

| +2

0 |

||||||||||

| ± 1 | ||||||||||

¹) These nominal sizes corresponds TS 1363 ISO 610/Marc 1998

MECHANICALS PROPERTIES

GRADE 1

GRADE 2

| 14×50 | 185 | 1,6 | 246 | 14 | 14 |

| 18×64 | 305 | 407 | 18 | ||

| 19×64,5 | 340 | 454 | 19 | ||

| 22×86 | 456 | 608 | 22 | ||

| 24×86 | 543 | 724 | 24 | ||

| 24×87,5 | 543 | 724 | 24 | ||

| 26×92 | 637 | 850 | 26 |

LENGTHS AND ALLOWABLE TOLERANCE OF MATHCING SHORTER MULTIPLE PITCH LENGHTHS

-Hanging vertically without any load.

LENGTHS AND ALLOWABLE TOLERANCE OF MATHCING LONGER MULTIPLE PITCH LENGHTHS

| 22×86 | 11 | 946 | ||||||

-Lengths serve as an example.

DIN 22252 chains, are tested and calibrated chains that you can use safely manufactured for conveyors used in mines. After the heat treatment performed specially in our induction machines, especially the proof and breaking load elongations are safely provided.

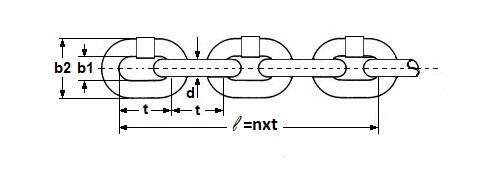

Marking of round-steel chain grade 2, nominal size 26×92 mm, lenght allowance according to table 1:DIN 22252-2-26×92-1

DIMENSIONS AND WEIGHTS

l |

||||||||||

| +2

0 |

||||||||||

| ± 1 | ||||||||||

¹) These nominal sizes corresponds TS 1363 ISO 610/Marc 1998

MECHANICALS PROPERTIES

GRADE 1

GRADE 2

| 14×50 | 185 | 1,6 | 246 | 14 | 14 |

| 18×64 | 305 | 407 | 18 | ||

| 19×64,5 | 340 | 454 | 19 | ||

| 22×86 | 456 | 608 | 22 | ||

| 24×86 | 543 | 724 | 24 | ||

| 24×87,5 | 543 | 724 | 24 | ||

| 26×92 | 637 | 850 | 26 |

LENGTHS AND ALLOWABLE TOLERANCE OF MATHCING SHORTER MULTIPLE PITCH LENGHTHS

-Hanging vertically without any load.

LENGTHS AND ALLOWABLE TOLERANCE OF MATHCING LONGER MULTIPLE PITCH LENGHTHS

| 22×86 | 11 | 946 | ||||||

-Lengths serve as an example.

Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763