Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763

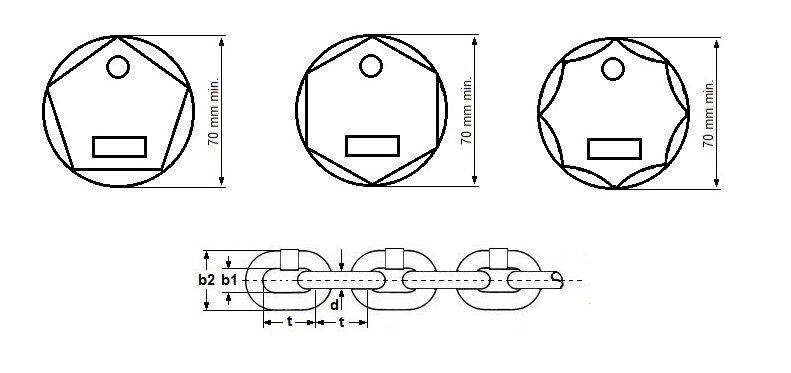

DIN 5684 chains, are tested and calibrated chains manufactured as G50 / G60 / G80 and for use in hoists. These DIN 5684 chains provide lifting your loads safely.

Marking of a round-steel chain, grade-8, diameter d=8 mm and tn=24 mm finish bright polished (bp) chain DIN 5684-8-8×24 bp

DIMENSIONS AND WEIGHTS

For grade 8:

Nominal diameter and pitchs in brackets should be avoided with new constructions.

-Perfect fit of a chain to the sprocket-wheel will be secured, if the sprocked-wheel is placed at manufacturer’s disposal.

-The chain link must not be stretched by the joining element of the hoist conveyor in the last link of the chain multiple pitch length.

GRADE 50

MECHANICAL PROPERTIES

| Mean stress at working load limit | |||

| Mean stress at manufacturing test force | |||

| Mean stress at acceptance proof force | |||

| Mean stress at breaking force specified | |||

| Total ultimate elongation | |||

| Surface hardness at all points | |||

| Ratio of mean stress at working load limit to mean stress at manufacturing test force to mean stress at breaking force specified | |||

GRADE 60

MECHANICAL PROPERTIES

GRADE 80

MECHANICAL PROPERTIES

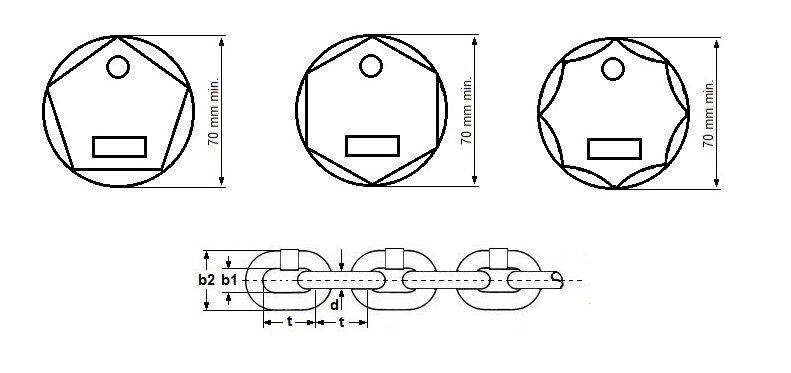

DIN 5684 chains, are tested and calibrated chains manufactured as G50 / G60 / G80 and for use in hoists. These DIN 5684 chains provide lifting your loads safely.

Marking of a round-steel chain, grade-8, diameter d=8 mm and tn=24 mm finish bright polished (bp) chain DIN 5684-8-8×24 bp

DIMENSIONS AND WEIGHTS

For grade 8:

Nominal diameter and pitchs in brackets should be avoided with new constructions.

-Perfect fit of a chain to the sprocket-wheel will be secured, if the sprocked-wheel is placed at manufacturer’s disposal.

-The chain link must not be stretched by the joining element of the hoist conveyor in the last link of the chain multiple pitch length.

GRADE 50

MECHANICAL PROPERTIES

| Mean stress at working load limit | |||

| Mean stress at manufacturing test force | |||

| Mean stress at acceptance proof force | |||

| Mean stress at breaking force specified | |||

| Total ultimate elongation | |||

| Surface hardness at all points | |||

| Ratio of mean stress at working load limit to mean stress at manufacturing test force to mean stress at breaking force specified | |||

GRADE 60

MECHANICAL PROPERTIES

GRADE 80

MECHANICAL PROPERTIES

Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763