Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763

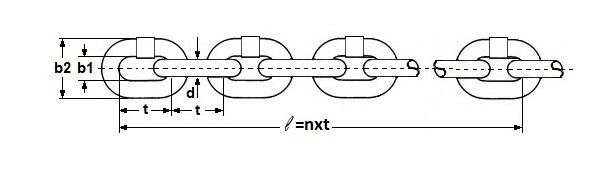

DIN 764 chains, are tested and calibrated short link chains that you can use for conveyors.

Marking of round-steel chain grade 3, calibrated, diameter d=18mm, and pitch t= 63mm: CHAIN DIN 764-3A-18×63

DIMENSIONS AND WEIGHTS

Taking into consideration chain bows see DIN 5699

Category A: for cogwheel

Category B: for plateroller

Perfect fit of a chain to the sprocket-whell will be secured, if the sprocked-wheel is placed at manufacturer’s disposal

MECHANICALS PROPERTIES

-The stated values of working load are valid only for speeds up to 1.2 m/s.

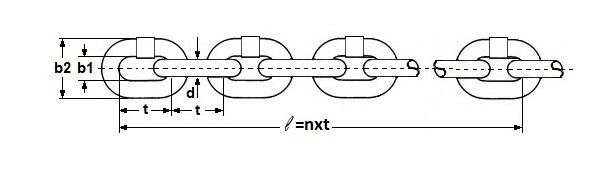

DIN 764 chains, are tested and calibrated short link chains that you can use for conveyors.

Marking of round-steel chain grade 3, calibrated, diameter d=18mm, and pitch t= 63mm: CHAIN DIN 764-3A-18×63

DIMENSIONS AND WEIGHTS

Taking into consideration chain bows see DIN 5699

Category A: for cogwheel

Category B: for plateroller

Perfect fit of a chain to the sprocket-whell will be secured, if the sprocked-wheel is placed at manufacturer’s disposal

MECHANICALS PROPERTIES

-The stated values of working load are valid only for speeds up to 1.2 m/s.

Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763