Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763

DIN 5685 chains, are non-tested and non-calibrated chains.

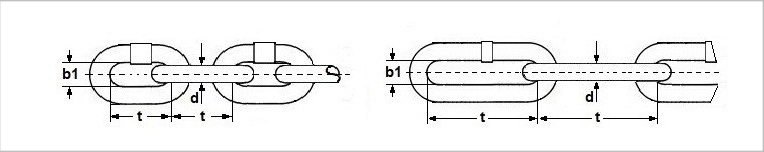

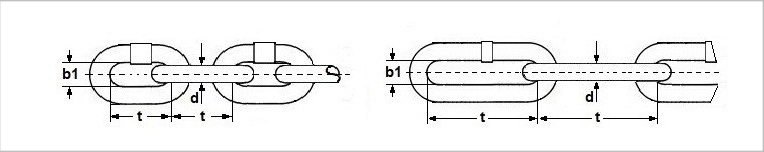

STRAIGHT LINK (G)

Marking of a round-steel chain with straight links (G), diameter d=4 mm and pitch t=19 mm : CHAIN G 4×19 DIN 5685

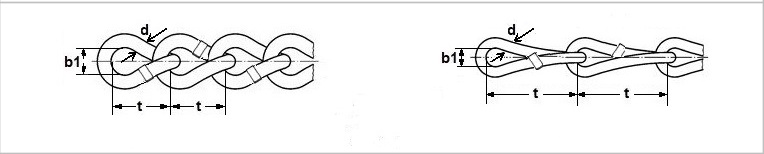

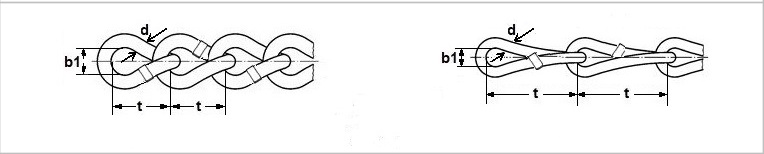

TWISTED LINK (X)

-With the chains form X the measures t and b become slightly smaller by twisting which makes the weight of twist link chains by about %6 higher.

-The transformation limit corresponds to the hardness 80 N/mm2. If it is transgressed one must expect permanent transformation contraction narrowing of chain links.

-The stated strain loads represent only calculated values.

DIMENSIONS AND WEIGHTS

| 4,5 | ± 0,23 | 8,1 | 1 | ||||

| 5 | ± 0,25 | 9 | 1,25 | ||||

| 6 | ± 0,3 | 10,8 | 1,6 | ||||

| 7 | ± 0,35 | 12,6 | 2,5 | ||||

| 8 | ± 0,4 | 14,4 | 3,2 | ||||

| 10 | ± 0,5 | 18 | 5 | ||||

| 12 | ± 0,6 | 21,6 | 7,1 | ||||

| 13 | ± 0,65 | 23,4 | 8 | ||||

DIN 5685 chains, are non-tested and non-calibrated chains.

STRAIGHT LINK (G)

Marking of a round-steel chain with straight links (G), diameter d=4 mm and pitch t=19 mm : CHAIN G 4×19 DIN 5685

TWISTED LINK (X)

-With the chains form X the measures t and b become slightly smaller by twisting which makes the weight of twist link chains by about %6 higher.

-The transformation limit corresponds to the hardness 80 N/mm2. If it is transgressed one must expect permanent transformation contraction narrowing of chain links.

-The stated strain loads represent only calculated values.

DIMENSIONS AND WEIGHTS

| 4,5 | ± 0,23 | 8,1 | 1 | ||||

| 5 | ± 0,25 | 9 | 1,25 | ||||

| 6 | ± 0,3 | 10,8 | 1,6 | ||||

| 7 | ± 0,35 | 12,6 | 2,5 | ||||

| 8 | ± 0,4 | 14,4 | 3,2 | ||||

| 10 | ± 0,5 | 18 | 5 | ||||

| 12 | ± 0,6 | 21,6 | 7,1 | ||||

| 13 | ± 0,65 | 23,4 | 8 | ||||

Industrial Chains

High Strength Lifting and Sling Chains

– DIN EN 818 – 2 / GRADE 80 (G80)

– GRADE 100 (G100)

– DIN 5687 / GRADE 50 (G50)

Hoist Chains

– DIN 5684 / G50-G60-G80

High Strength Mine Chains

– DIN 22252

Conveyor Chains

– DIN 764

– DIN 762

Short Link Calibrated Chains

– DIN 766

Non-Calibrated Chains

– DIN 5685

– DIN 763